What is Composite Extrusion?

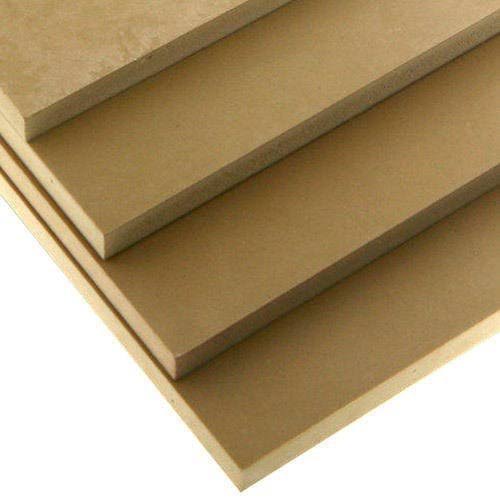

Composite extrusion is a process that combines wood or similar organic materials with thermoplastic resins to create versatile profiles with enhanced properties. This technology has seen significant growth in the market over the past decade. The profiles produced are known as Wood Plastic Composites (WPCs) and are created using a blend of wood flour, wood fiber, sawdust, or rice husk, mixed with plastic resins such as High-Density Polyethylene (HDPE), Polypropylene (PP), PVC, or ABS. These materials are then processed through extrusion to produce various shapes and profiles that offer the aesthetics of wood with the added benefits of thermoplastics.

Rajoo Bausano's Advanced WPC Technology

Rajoo Bausano's POLYWOOD technology leverages up to 80% wood powder to manufacture WPC profiles, including PVC/WPC flooring and WPC boards, doors, and frames. The company provides a comprehensive range of extrusion lines with outputs ranging from 200 kg/hr to 1200 kg/hr.

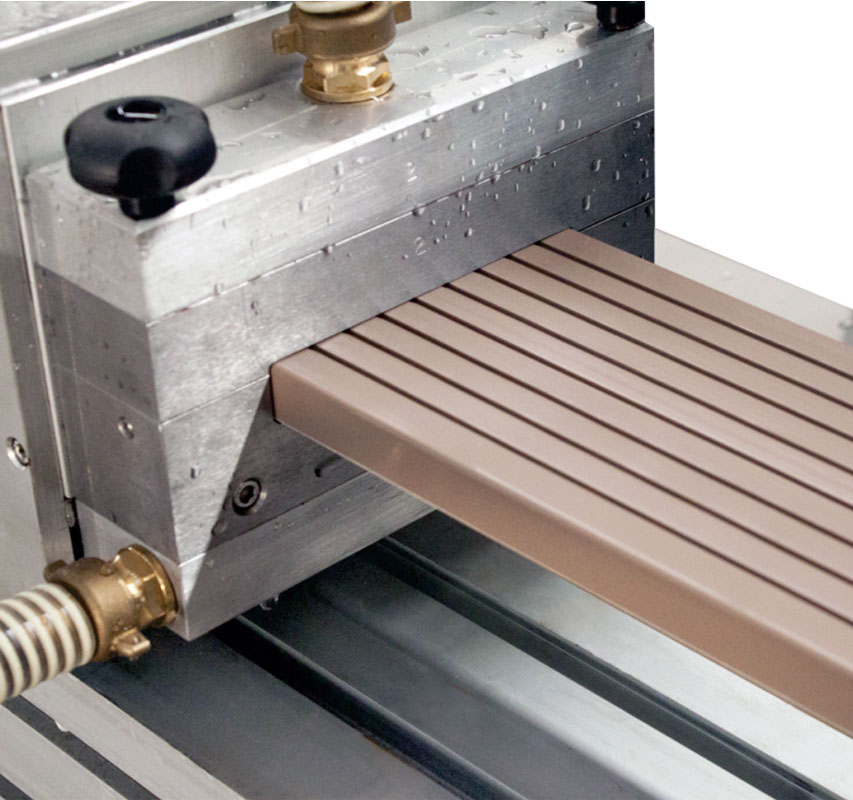

The Wood Plastic Composite Line includes a twin-screw extruder with a MULTIDRIVE system, a coat hanger-type die/profile die, calibrators, a calibrating table with a mold temperature controller, an embossing unit, a multi-roller take-off unit, edge trimming unit, cutting, and stacking unit.

The screw geometry in Bausano's extruders offers a wide processing window with a 36:1 L/D ratio, ensuring effective homogenization of natural fiber flour with polymers and optimal heat transmission. The extruders are equipped with a multi-vent system for moisture and volatile removal to enhance product quality. Additionally, a gravimetric/volumetric dosing system is available for precise control of the mixing ratio of polymers, sawdust, additives, profile-grinded scraps, and pigments.

ADVANTAGES of Wood Plastic Composite (WPC)

- Longer Durability: Resistant to weather conditions.

- Flame Retardant: Enhanced safety in various applications.

- Termite Proof: Protection against pests.

- High Resistance: To salt corrosion, moisture, bacteria, and UV rays.

- 100% Recyclable: Environmentally friendly.

- Aesthetic Appeal: Mimics the look of wood.

- Cost-Effective: Faster and cheaper joining compared to wood.

- Flexibility: Easy to bend for doors, windows, and decorative uses.

- Surface Treatments: Capable of hot stamping, direct painting, high-resolution printing, lamination, and CNC routing.

- Maintenance Free: Minimal upkeep required.

WOOD PLASTIC COMPOSITE APPLICATIONS

- Decking

- Flooring

- Wall cladding

- Door & Door frame

- Kitchen cabinet

- Garden bench

- Chairs

- Foamed Sheet/Board for Furniture

- Solid/Hollow doors

- PVC Door

- Flush door

- Roofing and many more

Bausano's WPC Granule Extrusion Lines

Bausano also specializes in extrusion lines for producing WPC granules, which can be further transformed into finished products through molding or extrusion using Bausano Twin or Single Screw Extruders. These granulation lines are designed for high performance and flexibility, allowing for the use of recycled materials and producing high-quality WPC profiles.

The extrusion lines from Bausano feature customizable and efficient designs, utilizing renewable raw materials for environmental protection. The MD Twin Screw extruders in the Twin screw MD Series, combined with a wide range of modular accessories, ensure ease of use, maintenance, and cleaning.

Key Features of WPC Extrusion

- Versatility: Can be processed similarly to wood.

- Durability: Resistant to corrosion, weather, and UV radiation.

- Termite Resistance: Effective against termite damage.

- Cost Efficiency: More affordable than traditional wood.

- Aesthetic Appeal: Comparable to wood in finish and appearance.

- Low Maintenance: Requires minimal maintenance and no special treatments for installation.